Customized mechanical engineering industry support solutions for your business growth.

Customized mechanical engineering industry support solutions for your business growth.

Blog Article

Top Tips for Effective Electric System Troubleshooting

Fixing electrical systems calls for a systematic technique, grounded in an extensive understanding of electric principles and safety and security protocols. By familiarizing oneself with circuit parts, making use of important devices, and adhering to a structured examination approach, experts can properly determine and resolve issues. The nuances of reliable repairing extend past mere technological understanding; recognizing exactly how to document searchings for and prioritize security can significantly influence end results. As we discover these important components better, it ends up being clear that understanding this procedure is not simply useful yet important for success in the area.

Understand the Fundamentals

Understanding the basics of electric systems is essential for effective troubleshooting, as a solid structure allows service technicians to detect and solve problems extra successfully. A detailed grasp of electrical principles, such as voltage, existing, resistance, and power, is important in recognizing the source of issues. Voltage is the electrical prospective difference that drives present with a circuit, while resistance opposes the flow of existing, impacting the overall functionality of the system.

Knowledge with circuit parts, including resistors, capacitors, diodes, and switches over, is additionally paramount. Each component plays an unique function in circuit behavior and can influence efficiency when malfunctioning. Additionally, understanding collection and parallel circuit configurations is crucial, as these setups affect the distribution of voltage and current within the system.

Professionals must be conscious of possible threats, such as shock and short circuits, to implement risk-free troubleshooting methods. By mastering these foundational ideas, technicians improve their ability to carry out reliable diagnostics and repair work, eventually leading to boosted efficiency and integrity of electric systems (electrical system troubleshooting).

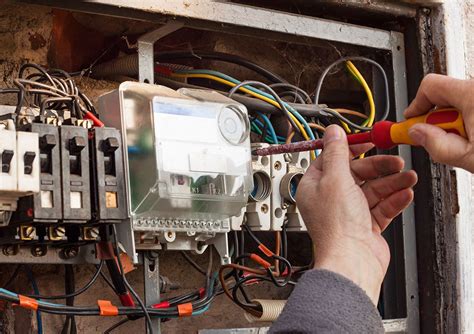

Gather Necessary Equipment

Efficient troubleshooting of electrical systems calls for the right collection of tools to detect and solve issues accurately. Necessary tools include a multimeter, which gauges voltage, current, and resistance, enabling for specific examinations of electrical components.

Furthermore, protected hand tools such as screwdrivers, pliers, and cord strippers are important for securely adjusting electric links. It is likewise suggested to have a circuit tester available to confirm the existence of voltage in electrical outlets and cables. For more complicated systems, a thermal imaging electronic camera can help spot overheating components, suggesting possible failures.

Follow an Organized Strategy

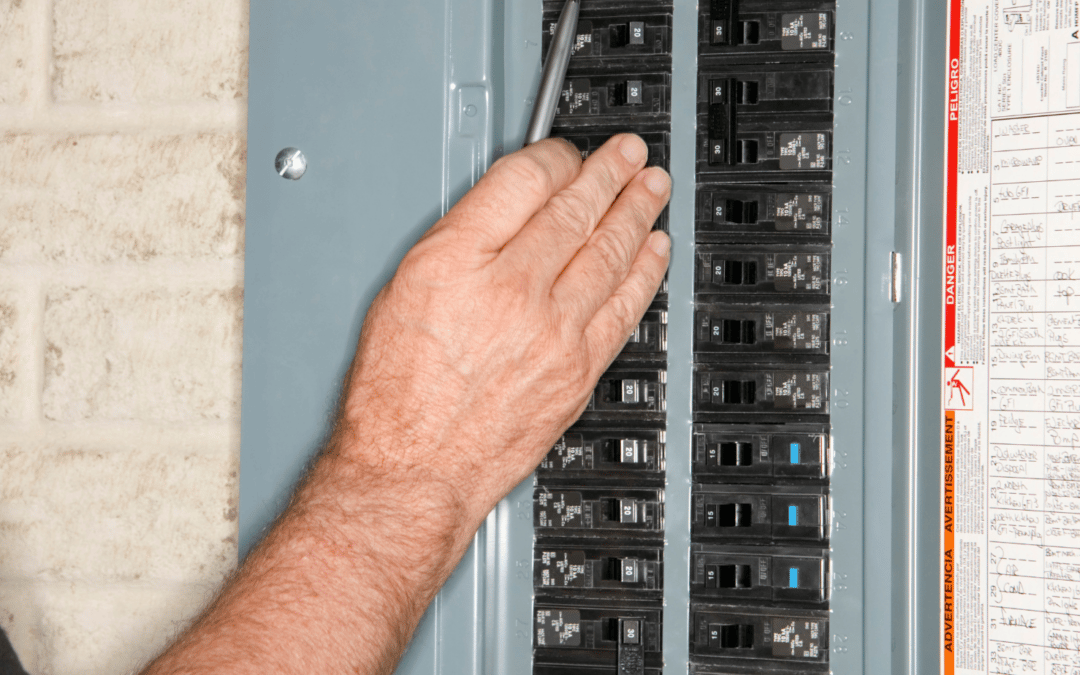

Having actually gathered the suitable tools, the following action in troubleshooting electric systems is to adhere to a systematic strategy. A methodical strategy makes certain that professionals can determine mistakes successfully and properly, decreasing downtime and protecting against unneeded repair services.

Begin by examining the system's schematic layouts and specifications. This involves monitoring each component methodically, starting from the power resource and functioning towards the tons.

Utilize these details testing equipment, such as multimeters and oscilloscopes, to gather objective information regarding voltage, current, and resistance at various points within the system. This empirical proof will assist your troubleshooting initiatives and help to validate or get rid of prospective sources of failure.

Additionally, think about environmental elements that may affect the system's performance, such as temperature changes or moisture access. A detailed inspection of electrical wiring, connections, and components will certainly ensure that all possibilities are made up.

Paper Your Searchings For

Detailed documents is essential in the troubleshooting procedure of electrical systems. This practice not just help in recognizing the root cause of the trouble however additionally serves as a recommendation for future repairing initiatives.

In addition, maintaining a log of parts replaced or fixings executed is important. This info supports stock administration and can help evaluate the long life and reliability of specific components.

Eventually, the documentation procedure should be complete yet succinct, making it possible for very easy retrieval and check here testimonial - electrical system troubleshooting. By prioritizing in-depth paperwork, specialists can create a beneficial data base that not just aids in current troubleshooting yet additionally empowers future maintenance initiatives, thereby enhancing overall system integrity

Prioritize Security Steps

Identifying the fundamental threats connected with electric systems is essential for guaranteeing safety during troubleshooting. Electric shock, burns, and equipment damages are simply a few of the prospective dangers that specialists deal with. Prioritizing precaution is not only a legal responsibility but also an ethical important that safeguards both the professional and the surrounding setting.

Prior to starting any type of troubleshooting task, professionals need to don proper personal safety tools (PPE), consisting of protected handwear covers, safety glasses, and flame-resistant clothes. Ensuring that the workspace is completely dry and devoid of mess can dramatically decrease the threat of accidents. It is vital to de-energize circuits before starting any work, validating that they are not live via the usage of a multimeter or voltage tester.

Developing clear communication methods with group participants is likewise vital; this guarantees that everybody knows possible threats and the status of the electrical system being serviced. Lastly, having an emergency situation feedback plan in location can prove important in the occasion of a case. By focusing on safety and security procedures, professionals can efficiently minimize dangers and cultivate a safer work environment.

Final Thought

Effective electric system repairing relies upon an extensive understanding of essential concepts and a systematic approach. By collecting vital tools, sticking to organized examination techniques, and meticulously documenting findings, the repairing procedure becomes more effective and trustworthy. Prioritizing precaution makes sure the well-being of people included and the honesty of the electric system. Applying these strategies will boost the fixing experience, leading to quicker resolutions and enhanced functional performance look at more info in electrical systems.

Report this page